Types of clutches:

Today we will discuss about types of clutches used in automobile industries. In an automobile, the engine produces power and this power is carry to the wheels by use of power train. The first element of this train is clutch. The main function of the clutch is to engage and disengages the engine to the wheel when the driver need or when shifting the gears. Basically clutch may be classified as follow.

Types of clutches:

These may classified as follow:

According to the method of transmitting torque:

1.

Positive clutch (Dog clutch):

In the positive clutch, grooves are cut either into the driving member or into the driven member and some extracted parts are situated into both driving and driven member. When the driver releases clutch pedal then these extracted parts insert into grooves and both driving and driven shaft revolve together. When he push the clutch pedal these extracted parts come out from grooves and the engine shaft revolve itself without revolving transmission shaft.

2. Friction clutch:

In this types of clutches, friction force is used to engage and disengage the clutch. A friction plate is inserted between the driving member and the driven member of clutch. When the driver releases the clutch pedal, the driven member and driving member of clutch, comes in contact with each other. A friction force works between these two parts. So when the driving member revolves, it makes revolve the driven member of clutch and the clutch is in engage position.

This type of clutch is subdivided into four types according to the design of the clutch.

- Cone clutch

- Single plate clutch

- Multi plate clutch

- Diaphragm clutch

A) Cone clutch:

It is a friction type of clutch. As the name, this type of clutch consist a cone mounted on the driven member and the shape of the sides of the flywheel is also shaped as the conical. The surfaces of contact are lined with the friction lining. The cone can be engage and disengage form flywheel by the clutch pedal.

B Single plate clutch

In the single plate clutch a flywheel is fixed to the engine shaft and a pressure plate is attached to the gear box shaft. This pressure plate is free to move on the spindle of the shaft. A friction plate is situated between the flywheel and pressure plate. Some springs are inserted into compressed position between these plates. When the clutch pedal releases then the pressure plate exerts a force on the friction plate due to spring action. So clutch is in engage position. When the driver pushes the clutch pedal it due to mechanism it serves as the disengagement of clutch.

C) Multip-plate clutch:

Multi-plate clutch is same as the single plate clutch but there is two or more clutch plates are inserted between the flywheel and pressure plate. This clutch is compact then single plate clutch for same transmission of torque.

D) Diaphragm clutch:

This clutch is similar to the single plate clutch except diaphragm spring is used instead of coil springs for exert pressure on the pressure plate . In the coil springs, one big problem occur that these springs do not distribute the spring force uniformly. To eliminate this problem, diaphragm springs are used into clutches. This clutch is known as diaphragm clutch.

3. Hydraulic clutch:

This clutch uses hydraulic fluid to transmit the torque. According to their design, this clutch is subdivided into two types.

A.) Fluid coupling:

It is a hydraulic unit that replaces a clutch in a semi or fully automatic clutch. In this type of clutch there is no mechanical connection between driving member and driven member. A pump impeller is blotted on a driving member and a turbine runner is bolted on the driven member. Both the above unit is enclosed into single housing filled with a liquid. This liquid serve as the torque transmitter form the impeller to the turbine. When the driving member starts rotating then the impeller also rotates and through the liquid outward by centrifugal action. This liquid then enters the turbine runner and exerts a force on the runner blade. This make the runner as well as the driven member rotate. The liquid from the runner then flows back into the pump impeller, thus complete the circuit. It is not possible to disconnect to the driving member to the driven member when the engine is running. So the fluid coupling is not suitable for ordinary gear box. It is used with automatic or semi-automatic gear box.

B.) Hydraulic torque converter:

Hydraulic torque converter is same as the electric transformer. The main purpose of the torque converter is to engage the driving member to driven member and increase the torque of driven member. In the torque converter, an impeller is bolted on the driving member, a turbine is bolted on the driven member and a stationary guide vanes are placed between these two members. This all parts are enclosed into single housing which filled with hydraulic liquid. The impeller rotates with the driven member and it through the liquid outward by centrifugal action. This liquid flowing from the impeller to turbine runner exerts a torque on the stationary guide vanes which change the direction of liquid, thereby making possible the transformation of torque and speed. The difference of torque between impeller and turbine depends upon these stationary guide vanes. The hydraulic torque converter is serve the function of clutch as well as the automatic gear box.

According to the method of engaging force:

1) Spring type clutch:

In this types of clutches, helical or diaphragm springs are used to exert a pressure force on the pressure plate to engage the clutch. These springs are situated between pressure plate and the cover. These springs are inserted into compact position into the clutch. So when it is free to move between these two members, it tends to expand. So it exert a pressure force on the pressure plate thus it brings the clutch in engage position.

2) Centrifugal clutch:

As the name in the centrifugal clutch, centrifugal force is used to engage the clutch. This type of clutch does not require any clutch pedal for operating the clutch. The clutch is operated automatically depending upon engine speed. It consist a weight pivoted on the fix member of clutch. When the engine speed increase the weight fly of due to the centrifugal force, operating the bell crank lever, which press the pressure plate. This makes the clutch engage.

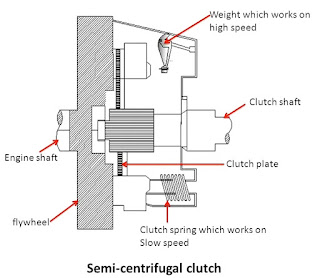

3) Semi- Centrifugal clutch:

One big problem occur in centrifugal clutch is that they work sufficient enough at higher speeds but at lower speed they don’t do their work sufficiently. So the need of another type of clutch occurs, which can work at higher speed as well as at lower speed. This type of clutch is known as semi-centrifugal clutch. This type of clutch uses centrifugal force as well as spring force for keeping it in engaged position. The springs are designed to transmit the torque at normal speed, while the centrifugal force assists in torque transmission at higher speeds.

4) Electro-magnetic clutch:

In the electromagnetic clutch electro-magnate is used to exert a pressure force on pressure plate to make the clutch engage. In this type of clutch, the driving plate or the driven plate is attached to the electric coil. When the electricity is provide into these coils then the plate work as the magnate and it attract another plate. So both plates join when the electricity provides and the clutch is in engage position. When the driver cut the electricity, this attraction force disappear, and the clutch is in disengage position.

Please comment if you have any queries..